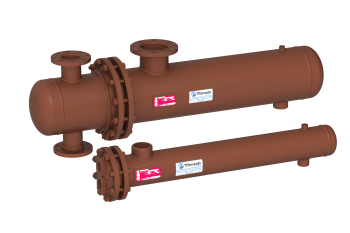

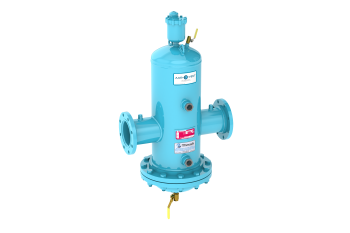

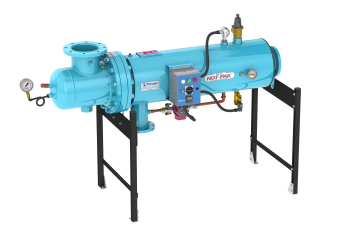

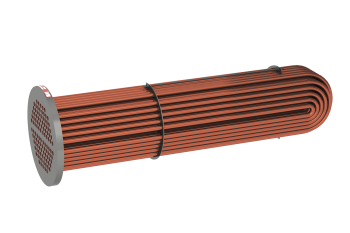

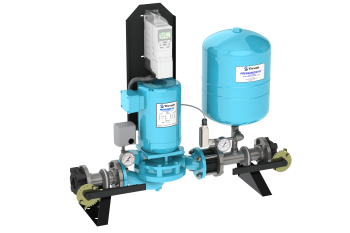

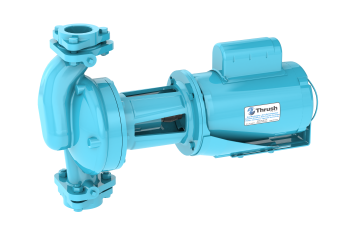

Hydronic System Solutions

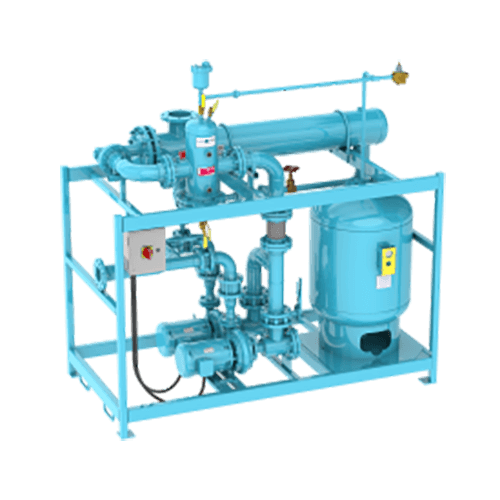

Thrush Co., Inc. has been solving the problems of the HVAC industry for decades by manufacturing a full line of products specifically engineered to improve efficiency, reduce maintenance, and provide long-lasting, trusted service. From quick, responsive service to custom hydronic solutions, we deliver for you.

If it's doable, we've got you covered

Sometimes complex challenges do require complex solutions, and that’s our cue. At Thrush, we’ve earned a reputation as forward-thinkers, puzzle-solvers, and maneuver-masters. In fact, it’s what we do best. Those retrofit projects that seem like nightmares? We daydream about those.

Get Started TodayFor All Your Hydronic Solutions, Think Thrush.

Ready to Start a Project?

Use our interactive Rep Locator Tool to Find a Thrush Co. Representative near you.

Find a Rep Near You